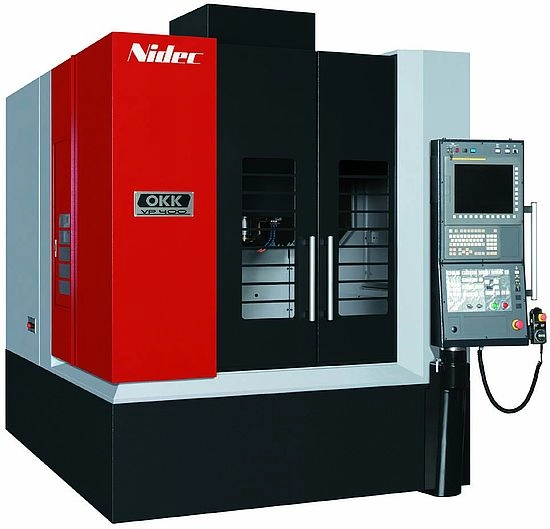

Vertical Machining Center One-of-a-kind, highly cost-efficient model that pursues the ultimate cutting performance and precision!

This is an upgrade of one of Nidec OKK's bestselling machines!! With its main unit made more rigid than before, this model now boasts better accessibility to its works, easier maintenance, and user-friendliness. As with its predecessor, each of VM43RII's feeding guide devices uses a highly precise and rigid rectangular sliding box guide way. In addition, with the use of the No.50 taper spindle, this model can machine a variety of works, ranging from general components to titanium and other difficult-to-cut parts.

Reviews

There are no reviews yet.