เวลาทำการ 8.30 – 17.30

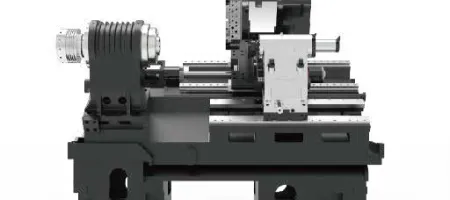

Bed

Spindle

Guide rail

| Item | CNC Lathe LT210 | Specifications |

| Machining capacity | Maximum swing over bed | 510mm |

| Maximum turning diameter | 320mm | |

| Recommended turning diameter | 210mm | |

| Maximum turning length | 500mm | |

| Bar workpiece diameter | 51mm | |

| Distance from spindle center to ground | 1050mm | |

| Stroke | X travel | 175mm |

| Z travel | 510mm | |

| Travel | Spindle speed | 4500rpm |

| Spindle interface specification | A2-6 | |

| Main motor power (rated/maximum) | 11/15kw | |

| Spindle through hole diameter | 66mm | |

| Servo axis | X/Z rapid traverse speed | 30/24m/min |

| Cutting feed rate | 1-10000mm/min | |

| Turret | Turret capacity | 12 Station Bot |

| Boring bar diameter | 40mm | |

| Turret type | Servo turret + hydraulic locking | |

| Main accuracy | Positioning accuracy | 0.008mm |

| Repeatabilit | 0.004mm | |

| Others | Machine footprint and height | 2570*2300*1750mm |

| Machine weight (apx.) | 3200kg | |

| CNC system |

FANUC 0iTF(SIEMENS 828D) |

Combitech Machinery Company Limited, a leader in industrial machinery for more than 30 years

Copyright © 2024 combitech. All rights reserved Developed by iWeb.cafe