เวลาทำการ 8.30 – 17.30

High-rigidity structure

Spindle

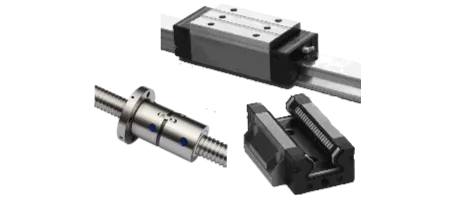

Linear guides and ball screws.

| Item | Gantry Machining Center LM1613L | Specifications |

| Travel | X-axis travel | 1600mm |

| Y-axis travel | 1300mm | |

| Z-axis travel | 600mm | |

| Distance from spindle end face to worktable | 200-800mm | |

| Gantry passing height | 870mm | |

| Gantry width | 1400mm | |

| Worktable | Worktable size |

1700*1200mm |

| T-slot quantity/size/spacing | 7*22*150 | |

| Maximum loading capacity | 3000kg | |

| Spindle | Spindle speed | 50-12000rpm |

| Drive mode | Direct drive | |

| Spindle motor torque (rated/maximum) | 52.5/118Nm | |

| Main motor power |

11/15kw |

|

| Servo axis | X/Y/Z rapid traverse speed | 15/18/18m/min |

| Cutting feed rate | 1-10000mm/min | |

| Counterbalance method | None | |

| Minimum feed | 0.001mm | |

| Tool/tool magazine | Tool magazine type | Passing height of gantry |

| Shank specification | BT-40 | |

| Max tool length | 300mm | |

| Main accuracy | Positioning accuracy(X/Y/Z) | 0.012/0.01/0.01mm |

| Repeatability(X/Y/Z) | 0.01/0.008/0.008mm | |

| Others | Machine footprint and height | 4450*4024*3200 |

| Machine weight (apx.) | 11000kg | |

| CNC system | FANUC 0iMF PLUS |

Combitech Machinery Company Limited, a leader in industrial machinery for more than 30 years

Copyright © 2024 combitech. All rights reserved Developed by iWeb.cafe